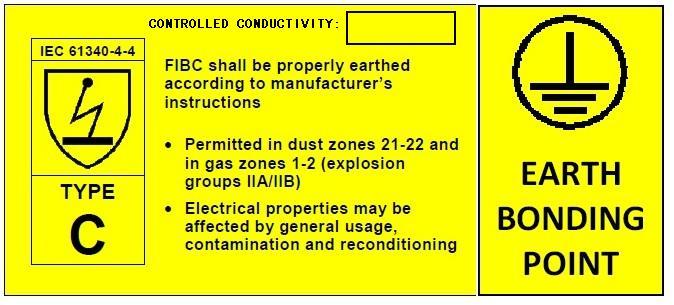

Type C FIBCs refer to the class of FIBCs that actually protects against dangerous static discharges through grounding of the bag itself during the filling and discharging processes. These bags are safe when grounded because any electrostatic potential that builds up as a result of rapid filling or discharging quickly and safely exits the bag to ground via the network of conductive fibers woven into the fabric of the bag. This is true as long as the bag continually remains grounded.

As a recognized leader in the bulk packaging industry and FIBC solutions , Procon Pacific is the go-to source for your conductive FIBC needs. Our extensive expertise includes complete FIBC Type C solutions. What’s more, our comprehensive knowledge of Type C FIBCs means we can provide you with the product that meets your precise needs. Whatever conductive bulk bags best suit your purposes, you can be sure that Procon Pacific will provide the products that deliver. Our knowledgeable personnel will help guide you to the solution that will meet all of your needs while protecting your workforce and keeping your facility safe.